![]() The Pacific War Online Encyclopedia

The Pacific War Online Encyclopedia

|

| Previous: Loftus-Tottenham, Frederick J. | Table of Contents | Next: Loiwing |

National

Archives

#80-G-182880

If there was one area of the military art in which Americans excelled, it was logistics, the science of moving, supplying, and maintaining military forces. Sometimes defined as the economics of warfare, logistics takes in everything from the calculation of production requirements to the delivery of rations and ammunition to the rifleman in the front line. A separate article covers actual production, while this article focuses on the movement of matériel from its point of production to the combat zone. This was a particular challenge in the Pacific, where vast distances separated major bases.

Commanders contemplating a military operation needed estimates of the supplies required to support the forces that would carry out the operation. This was mostly a matter of arithmetic, but since the rate of consumption of munitions depended on the duration and intensity of combat during the operation, good judgment was also required. The commander also needed a plan for establishing and securing adequate lines of communication from the source of supply to the men at the front. A commander who undertook an operation for which he had inadequate supplies, or who failed to protect his lines of communication, risked disaster. Contrariwise, a commander who was able to threaten enemy lines of communication could seize and hold the initiative by forcing the enemy to react to the threat. Thus, securing one's own lines of communication while threatening the enemy's was a major element of strategy.

There is an apocryphal story claiming that Admiral Ernest King once made the remark, "I don't know what the hell this 'logistics' is that Marshall is always talking about, but I want some of it." In fact, the U.S. Navy had put considerable effort into studying the problem of supplying a fleet during a drive across the Pacific to the Philippines and Japan, and no one understood the importance of logistics better than King (Hornfischer 2011):

The war has been various termed a war of production and a war of machines. Whatever else it is, so far as the United States is concerned, it is a war of logistics. The ways and means of supply and support our forces in all parts of the world — including the Army of course — have presented problems nothing short of colossal and have required the most careful and intricate planning. The profound effect of logistics on our strategic decisions are not likely to have full significance to those who do not have to traverse the tremendous distances in the Pacific. It is no easy matter in a global war to have the right materials in the right places at the right times in the right quantities.

The U.S. Navy did pioneering work on underway refueling and had a good idea of what kind of fleet train would be needed in a Pacific war. However, there was only limited peacetime funding for the fleet train, and early U.S. naval operations struggled with logistics. The Wake relief expedition was crucially delayed by a lack of modern oilers and inexperience with underway refueling, and by March 1942 the crew of Lexington, deployed to the undeveloped South Pacific, was down to subsisting on canned spinach and beans. Nimitz stationed the surviving battleships of Pacific Fleet on the West Coast, not only because he had seen the evidence of what naval air power could do when he arrived at Pearl Harbor, but because he lacked tanker support to keep the huge ships fueled. The worldwide shortage of shipping, and the "Germany First" policy, meant that it would take time to properly organize the fleet train. However, American logistics were simply dazzling once the Central Pacific offensive got underway in late 1943.

Japanese logistics were little short of appalling, and it has

been estimated that as many as 60% of Japanese military deaths during the war were

attributable to starvation. Logistics had been

persistently neglected from the time of the First Sino-Japanese

War of

1894-1895. The Japanese General Staff

did not originally include a

logistics branch and transport officers were ineligible for

admission

to the War College. At the time of the Russo-Japanese War of 1905, only

4 percent of military academy graduates were choosing to go into

the

logistics corps. The weakness of Japanese logistics was exploited

by the Allies through such strategies as island hopping. But even

the American logistical apparatus sometimes proved inadequate in

the Pacific, particularly early in the war, when American

production

was still ramping up and commanders were discovering the flaws of

peacetime doctrine.

Military forces required a minimum level of supply simply to maintain themselves. Movement and combat required additional supplies beyond the minimum requirements for maintenance. A unit that was short of supplies had to curtail its activities, and if supplies dropped below minimum requirements, the unit faced gradual disintegration. Equipment would break down and morale would collapse as troop began to suffer from hunger. Contrariwise, well-supplied troops could conduct vigorous combat operations or, if not in actual contact with the enemy, carry out realistic training and conduct regular thorough reconnaissance.

Units of measure. In the Pacific War, the ability of

both the Allies and Japanese to sustain forces in the field was

limited by

their shipping

capacity. As a result, at the theater

level, supply requirements were calculated in units relevant to cargo ships.

A ship has only so much space for its cargo. Gross tonnage is the entire enclosed space of a ship, measured in register tons of 100 cubic feet (2.83 cubic meters). Net tonnage is the space that can actually be used for cargo, also measured in register tons. Logisticians prefer the measurement ton, which is equal to 40 cubic feet (1.13 cubic meters) of cargo or cargo space. The capacity of the average ship in measurement tons was roughly equal to 1.775 times its gross register tonnage.

A ship can be loaded with only so

much weight of cargo

before it sits dangerously low in the water. A cargo ship has

a deadweight

tonnage equal to the maximum permissible weight of ship's gear,

supply,

and

personnel as well as cargo, measured in long tons of 2240 pounds

(1.016

metric tons). The

deadweight effective lift of a ship is the maximum cargo weight

and is

typically about 80% of deadweight tonnage. The deadweight lift of

the average ship was about 1.2 times

its gross register tonnage.

In practice, for typical military cargoes, it was volume rather than weight that limited carrying capacity. For planning purposes, the U.S. Army adopted a figure of 2.56 measurement tons per long ton of average military cargo and 1.44 measurement tons per long ton of Lend-Lease cargo. An unusually compact cargo, such as oil in 55-gallon (208 liter) drums, might take 1.37 measurement tons per long ton.

A Liberty

ship

had a deadweight tonnage of

about 10,800 tons, corresponding to a lift of about 8640

tons. Its cargo

capacity by volume was about 12,506 measurement tons, for a ratio

of

1.45

measurement tons per long ton. Ordinary merchant ships tended to

have a

greater measurement tonnage to

lift

tonnage ratio: 1.84 for a C-3

standard cargo vessel. This demonstrates

that military cargo was generally volume limited rather than

weight

limited. Commercial cargo varied widely, but it was typically much

more

compact than military cargo and was weight limited rather than

volume

limited.

Bulk liquids were much more efficiently transported by tankers than in 55-gallon barrels on ordinary cargo ships. Bulk oil has a measurement ton to long ton ratio of almost exactly 1. A T-2 tanker could carry 141,000 barrels of oil, equal to 5,922,000 gallons (22,417,000 liters) or about 18,972 long tons. Converted Liberty tankers (ZET-1) could carry 65,000 barrels or about 8,746 tons. Oil has a specific gravity of about 0.9 and gasoline has a specific gravity of about 0.75, so the weights corresponding to a given value should be adjusted accordingly. In practice, the figure for oil is usually "close enough."

The available shipping capacity was only part of the story. The

military planner also had to factor in the turnaround time for

shipping, which determined how many measurement tons of cargo

could be

delivered per month. During the period June-December 1942, the

total

measurement tons of cargo delivered per deadweight ton of shipping

was

0.42 in the Pacific and Far East. In this same time period, there

was

3.3 deadweight tons of shipping in the Pacific for each American

soldier deployed against Japan. This

was about 2.5 times the shipping required to support the

equivalent

manpower in Europe, mostly because of the greater distances and

poorer

port facilities involved.

Ground forces. In 1942, each American infantry division required about 6.8 measurement tons per man for its initial overseas deployment, or about 105,000 measurement tons for the whole division. This corresponded to about 60,000 deadweight tons of shipping, equivalent to about six cargo ships. An armored division required 17.9 measurement tons per man or a total of 260,000 measurement tons or fifteen cargo ships. Medical and engineering units were comparable to infantry while artillery units were in the 11-14 measurement ton per man range. By late 1943, the requirements had been cut down to about 4.4 tons per man for infantry and 13.1 tons per man for armor.

Once overseas, each man required

about 45 pounds (20 kg) of supplies

per day. These were broken down into five categories for

planning purposes by

the U.S. Army: 6.22 pounds (2.82 kg) of rations and other consumables

(Class I), 3.11 pounds

(1.41 kg) of clothing,

replacement vehicles, and other general supplies (Class II), 10.67

pounds (4.84 kg) of fuel

and lubricants (Class III), 15.46 pounds (7.0 kg) of medical,

motor

maintenance,

quartermaster,

construction, and other miscellaneous supplies (Class IV), and

9.58

pounds

(4.35 kg) of

ammunition (Class V). The figures for fuel (Class III) only

accounted for

about 10% of fuel usage; the remainder was shipped in bulk tankers

and

was

calculated separately. A division slice

of 40,000 men, plus two air

wing slices of 5000 men each, required 1600 tons of supplies daily

(1100 tons dry cargo, 475 tons bulk petroleum products, and 25

tons of

replacement vehicles.) If we take as representative the figure of

0.42

measurement tons delivered per month per deadweight ton of

shipping,

and 2.56 measurement tons per long tons of military supplies, then

the

division slice plus air slices required almost 300,000 tons of

shipping

for its sustenance.

The ration allowance for an American infantryman

in the Pacific was very generous at 4758 calories per day. By

contrast,

a British civilian in 1941

was given a ration of about 2800 calories

per day, while a Japanese civilian was already down to 2000

calories

per day before the attack on Pearl Harbor and would drop to 1680

calories per day in 1945.

British military allowances were significantly less generous than American. During the the battle of Imphal, the British IV Corps required 540 tons of supplies per day, or about 18 pounds (8 kg) per man per day. Japanese allowances were less generous still; during the planning for U-Go, 31 Division was promised ten tons of supplies per day (which, as it turned out, were never provided.) This was equivalent to about a pound (450 grams) per man per day. Japanese infantrymen in the South Pacific were sometimes allotted as little as 600 grams (1.3 lbs) of food per day while in combat, which if supplied as uncooked rice translated into a meager 2160 calories per day. A more typical ration was a kilogram (2.2 lbs) per day of rice, soybean paste (miso), powdered soy sauce, and salt, to be supplemented with whatever could be foraged locally. Emergency rations consisted of dry, tasteless crackers called kammempo.

In the U.S. Army, the day of supply was used for strategic

planning of

production and allocation of shipping between theaters. It took

into account both time in combat and time in reserve. Combat officers

responsible for tactical

planning used the unit of

fire, which roughly corresponded to the amount of ammunition

consumed in one day of heavy combat. The unit of fire was not

regarded as a rigid allowance: A combat formation

might expend several units of fire in a particularly heavy day of

combat, while a formation encountering only light resistance might

use

much less than a unit of fire per day.

Air forces. Aircraft

consume vast quantities of high-octane gasoline. A Catalina

patrol squadron (twelve aircraft) conducting routine patrols with

one-third of its aircraft each day would consume about 5600

gallons of

fuel per day or about 600 tons per month. Consumption would soar

during

alerts, when the squadron would likely put as many aircraft into

the

air as possible. The air wing of a carrier conducting

two deck load

strikes per day would consume as much as 36,000 gallons of fuel

per

day, a rate which would exhaust the gasoline stores of an Essex-class carrier

in less than a week.

A heavy bomber sortie at full load would consume some four tons of bombs and half a ton or more of gasoline, plus smaller amounts of machine gun and cannon ammunition. Thus a raid by a full bomber group (72 aircraft) would consume almost 300 tons of bombs and over 35 tons of gasoline. When one factors in other stores and replacement aircraft and parts, it is no wonder that an Allied airfield typically required unloading facilities capable of handling 1000 tons per day.

Naval forces. Naval fleets consumed oceans of fuel oil. A

well-designed capital ship consumed fuel at the rate of around 0.7

to 0.9 lbs (0.3 to 0.4 kg) of oil per shaft horsepower per hour.

In March 1942, Fletcher

calculated that

Task Force 17 (Yorktown, two cruisers, four destroyers) expended almost

5800

barrels of fuel oil per day at normal patrol speed of 15 knots.

Carrier

task forces on combat patrol typically had to refuel every six to

seven

days. By late

1943, the advanced

bases in the central Pacific required nine commercial tankers to

replenish fuel at the rate of 600,000 barrels (95,000,000 liters)

per

month. During the Marianas

campaign, in July 1944, six fleet

oilers and 40 chartered

tankers delivered almost 4,500,000 barrels of oil, 275,000 barrels

of

diesel fuel, and 8 million gallons of aviation gasoline into the

forward areas. Total

fuel oil issue in the Pacific was 17,000,000 barrels in 1942 and

28,000,000 barrels in 1943, the latter almost twice the total

commercial exports of petroleum products from the United States in

1941.

During the same campaign, American forces in the Marianas expended 6378 rounds of battleship ammunition; 19,230 rounds of cruiser ammunition; and 140,000 rounds of 5" (127mm) ammunition. Seven units of fire went ashore with the initial assault troops.

Expenditures continued to climb as the Allied counteroffensive rolled forward. During the first day of the landings at Iwo Jima, the bombardment force (consisting of six battleships, nine heavy cruisers, and nine destroyers) had fired a total of 475 16" (406mm) shells, 1325 14" (356mm) shells, 175 12" (445 mm) shells, 2100 8" (203mm) shells, 3000 6" (152mm) shells, and 36,260 5" (127mm) shells. This added up to about 8000 tons of munitions.

Total shipments from the West Coast in the first six months of 1943 included 707,557 tons to the Central Pacific and 856,645 tons to the South Pacific. About 70% of tonnage to the Central Pacific was construction materials, while only 30% of shipments to the South Pacific were construction materials. Shipments of combat and ordnance materials were 34,000 tons to the Central Pacific and 100,000 tons to the South Pacific, and shipments of petroleum products totaled 15,000 tons to the Central Pacific and 214,000 tons to the South Pacific. It was clear which area was the focus of operational activity in the first half of 1943. In addition, the Navy concluded that the service units sent to Hawaii in anticipation of the Central Pacific offensive had been put to use on local projects rather than be left sitting idle, and these projects had gotten completely out of hand.

Total naval shipments to the Pacific in 1944 were 5,522,000 tons.

Even this remarkable achievement was barely adequate to keep up

with

the Allied counteroffensive, whose schedule was repeatedly moved

up,

with the Marianas

invaded two and a half months ahead of schedule and Leyte two months ahead of

schedule.

It was not sufficient for the military commander to determine his

supply requirements and for the home front to produce the

supplies. It

was often a long ways from the point of production to the combat

front,

and especially so in the Pacific War. Immense flows of supply

required

an equally immense transportation infrastructure to get the

supplies

where they were needed.

By Sea. In the Pacific, almost all men and supplies

were transported across water for at least part of their

journey

from the homeland to the combat zone. Dry cargo was transported in

cargo ships and bulk

liquids (mostly gasoline and fuel oil) by tanker. The fighting man himself

was deployed to the combat theaters via transport ship. Travel by

ship was relatively slow, but it was far more economical than

travel by transport

aircraft, truck, or even

by railroad.

Cargo ships typically could advance about 240 nautical miles (440 km) a day. Transports, which were usually faster, could do 360 nautical miles (660 km). A ship typically took almost as long to load and unload as it spent at sea, as the longer routes to the far Pacific ended at inadequate ports with long unloading times. In 1943, turnaround times were 32.2 days for transports and 41.6 days for cargo ships to Hawaii from San Francisco; 77.9 days for transports and 133.6 days for cargo ships to the South Pacific from San Francisco; 69.4 days for transports and 115.3 days for cargo ships to the Southwest Pacific from San Francisco; 55.8 days for transports and 42.1 days for cargo ships to Alaska from Seattle; and 185.1 days for cargo ships to India from the U.S. East Coast.

Japanese cargo handling was quite efficient, and it was estimated

by Allied intelligence

that the Japanese could unload a combat-loaded ship of 5000 gross

tons in three days in a proper port, or six days by lighter.

Availability of shipping was the chief limiting factor on what the Allies could undertake throughout the war. In December 1941 the Americans had perhaps 130 oceangoing passenger ships suitable for military use. Of these, six were already in Navy hands and assisting British troop movements in the Indian Ocean. Another 20 were awaiting conversion to naval auxiliaries, and 25 combat loaders were ordered held in reserve for any amphibious operations. Eventually the Navy was persuaded to cancel conversion of some of the most capacious passenger ships to auxiliary carriers.

The shortage of amphibious

assault shipping was a particularly strong constraint in the

Pacific. By June 1944 the allocation in the Pacific was as

follows:

| Location |

APA |

AKA |

APD |

XAP |

AGC |

LSD |

LSI |

LCI |

LST |

LCT |

LCM |

LCVP |

LCA |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| U.S. West Coast |

3 |

1 |

0 |

0 |

0 |

0 |

0 |

41 |

0 |

1 |

60 |

181 |

0 |

| Central Pacific |

25 |

8 |

13 |

0 |

1 |

5 |

0 |

72 |

72 |

70 |

281 |

1105 |

0 |

| South Pacific |

16 |

5 |

2 |

0 |

1 |

3 |

0 |

13 |

33 |

60 |

215 |

751 |

0 |

| Southwest Pacific |

4 |

1 |

5 |

0 |

1 |

1 |

0 |

56 |

30 |

70 |

702 |

442 |

0 |

| British Far East |

0 |

0 |

0 |

0 |

0 |

0 |

1 |

4 |

0 |

2 |

67 |

0 |

46 |

Thus, at the time of the Marianas campaign, there was sufficient assault shipping in the Central Pacific for about two divisions, and the combined shipping resources in the South Pacific and Southwest Pacific were sufficient for less than two divisions. The invasion of the Marianas required the loan of many of the attack transports in the South Pacific, plus the use of a significant number of ordinary (non-APA) transports pressed into the role of assault shipping.

Shipping (and the associated supplies) were coordinated by the Americans through ports of embarkation, which thus were major control points in the supply chain. San Francisco was the port of embarkation for the Pacific, Los Angeles for the China-Burma-India theater, and Seattle for Alaska. Each such port had associated staging camps, such as Camp Stoneman for San Francisco. Formations were supposed to arrive at the staging camps already fully trained and equipped for overseas movement, but this was not always the case. Troops were usually moved through the camps in less than two weeks, but the time could be longer for troops needing additional equipment or training.

The Japanese estimated that a division slice required about

125,000 tons of shipping to be moved over long distances. The

requirement nearly doubled for movement near the front line, where

combat loading was required. An infantry regiment required 14,000

tons of shipping to move long distances, while an artillery

regiment required about 24,000 tons of shipping.

By Land. Shipping is a highly efficient form of transport.

Whereas transport by ship cost about $0.001 to $0.005 per ton-mile

in

1995, the corresponding cost was $0.003 to $0.015 per ton-mile by

river barge, $.02 to $.04 per

ton-mile by rail, and $.04 to $.10 per ton-mile by truck.

These costs would have been much smaller (due to inflation) in

1942 but the relative costs

were likely similar. However, ships must discharge their cargoes

at the

waterline for distribution

inland by other means.

River barges are the next most economical form of transport, but navigable rivers are relatively uncommon and are dictated by natural geography. Construction of artificial canals is a major work of civil engineering that is also highly constrained by geography.

Railroads are next in efficiency to river barges. Like canals, they require civil engineering work, but the effort required is far less and is less strongly dictated by geography. The Japanese built the Burma-Siam railroad using slave labor in just under a year, working from both ends to the middle over a distance from each end of 129 miles (208 km) for a rate of construction of about 0.4 miles (0.6 km) per day. Construction rates could be much greater in easier terrain with more modern equipment and professional labor, and much less in very difficult terrain requiring bridging or tunneling. Total mileage of railroads was a useful indicator of the overall economic development of a region; it follows that much of the South and Southwest Pacific areas lacked railroad infrastructure. China also lacked railroads, with just a few major north-south and east-west lines dictating the avenues of advance of the Japanese Army, which was highly reliant on rail transport.

Like ships, rail cars spend a significant fraction of their time

being loaded and unloaded. The U.S. Army estimated that the

average

movement of rail cars in the United States during the war was 51.7

miles per day, including days spent at sidings. Interservice

cooperation to ensure rail cars were fully loaded for movement, by

combining cargoes, was relatively good in the United States; I

have no

figures for Japan, but based on the known lack of cooperation over

merchant

shipping and factory space, I suspect such cooperation in rail

usage was nonexistent.

It took 63 trains totaling 1882 cars to move an infantry division

and all its equipment in the United States.

Corresponding figures for an armored division were 69 trains

totaling

2221 cars. A Japanese division would likely have required

considerably

less rolling stock, both because the division was generally

smaller and

less heavily equipped, and because the Japanese would likely

tolerate a

considerably higher level of discomfort in the troops.

Transport of supplies away from raillheads relied on motor vehicles or pack animals. The Japanese estimated that their field armies could operate only within 150 to 180 miles (240 to 290 km) of a railhead during the fighting in China. American armies had both higher logistical requirements and greater motorization than the Japanese, but they were able to operate at a significantly greater distance than 180 miles from port facilities during the northwest Europe campaign, via the "Redball Express." None of the Pacific campaigns involving large American formations took them further than sixty miles from shore, but, had the Americans fielded large armies in China or Burma, it is likely that their logistical radius would have been at least equal to that of the Japanese, and probably considerably greater.

For the Americans in the Pacific, logistics meant naval logistics until the invasion of Luzon in January 1945. All operations prior to that time drew their supplies across a chain of naval bases to the landing beaches, and ground troops rarely ventured far inland. This changed when troops landed at Lingayen Gulf were expected to race 110 miles (180 km) south to Manila. Krueger discovered that 6 Army had "practically no stocks of Bailey bridging, floating bridge equipment, and similar vital engineer items ... Our greatly overtaxed means of transportation were not, in fact, materially relieved until the bulk gasoline pipeline was laid from Lingayen Gulf to Dau, ... the railroad to San Fernando ... rehabilitated, and the port of Manila opened again" (quoted by Morison 1959). Ground logistics would again be taxed during the battle of Okinawa, where heavy rains would turn the battlefield into a morass impassable to trucks and difficult even for tracked vehicles to cross.

The British Indian Army showed

considerable ingenuity in highway construction. "Hessian" matting

was asphalt-impregnated burlap which

could be laid

very quickly using a special "stamplicker" roller that applied

solvent

to soften the matting as it was laid. This was used extensively

for rapid road construction during Slim's Burma campaign of 1944.

The British referred

to it as bithess.

it

came in rolls fifty yards (45.7 m) long and one yard (91 cm) wide

and

was laid on a packed roadbed such that the strips overlapped by

about

eight inches (20 cm). However, Hessian matting does not seem to

have

seen much use in the

Pacific. Its chief drawback was that it required vast amounts of petroleum products: The British

estimated that a gallon each of gasoline

and diesel fuel was required to lay a yard of roadway. For limited

roadway construction around bases, the Americans used Marston matting, but this

was far too expensive for construction of lengthy highways.

By Air. Transport by air is the fastest but by far the most expensive means of transportation. The Axis made only limited attempts to supply troops by air, often with disastrous consequences (as at Stalingrad in the European theater.) The Allies had the resources for greater experimentation with air transport, and this occasionally proved decisive; but the greatest Allied experiment in air supply, the airlift over "The Hump", must be judged a costly failure from a purely logistical perspective, though perhaps its importance was mostly political. Likewise, the tactics of deep penetration with air resupply adopted by the Chindits must be judged as not cost effective. More successful was the rapid movement and resupply by air of Slim's forces during the Imphal campaign. However, this was an emergency expedient rather than a permanent supply chain, and reopening the road to Dimapur through Kohima was the turning point of the campaign.

Permanently supporting a division in the field by air, at the rates established for American troops supplied by ocean transport, would have required about 116 sorties per day by C-47 Skytrains. Because of the limited range of air transports, this would not have eliminated the need for ocean transport to bring the supplies to airfields within range of their final destination. The value of air transport was in rapid relocation of troops and in reaching troops that were cut off from normal supply chains, which were far more efficient.

It is striking that most of the largest experiments in air

logistics

were carried out in the Southeast Asia and China theaters, where

logistical infrastructure was lacking and the Japanese had

successfully

cut normal supply chains. Most of the supplies flown in to China

went

to maintaining the supply chain itself, with the residue used

almost

entirely to support air operations. It was in China that the first

large-scale experiments with aerial tankers (converted B-24 Liberators)

took place, though aerial refueling was not attempted until long

after

the war was over. These experiments proved pitifully inadequate to

support the B-29

Superfortress

groups that were initially assigned to China, and these were

eventually

relocated to Tinian, where

they could be supplied by ocean transport.

Delivery of supplies directly from the point of production to the front line was impractical, because combat was episodic and rate of consumption of supplies varied far too dramatically for production and delivery to keep pace. Thus, supplies were initially shipped to rear area bases, where they could be stockpiled close to the point of use. Rear bases in turn distributed supplies to forward bases, and from there to supply dumps close to the front lines. At each stage, the ideal quantity of supplies to stockpile was sufficient to cover any sudden increase in consumption without wastage. When the force being supplied held the initiative, its commander could make preparations for the next operation by building up dumps of supplies adequate to support the operation.

The supply chain began with ports in the home country. San Diego, the Los Angeles area, San Francisco Bay, and Puget Sound were major base

areas for U.S. forces, with additional supplies coming through the

Panama Canal.

British supplies came around the Cape of Good Hope or (later in

the

war) through the Suez Canal. Major Japanese home port areas

included Tokyo Bay, Nagoya, Osaka, Hiroshima and other ports on

the Inland Sea, Kagoshima, and Nagasaki. Important rear area

bases were located at Pearl

Harbor, in southern Australia,

and in India for the Allies and in Formosa, Indochina, and coastal

China for the Japanese. Forward bases moved with the fighting

front, but included such storied ports as Manila, Truk, Rabaul, and Espiritu Santo.

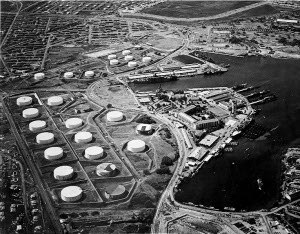

A typical Allied naval base, Noumea, was equipped with a fuel oil tank farm with a capacity of 53,000 tons and a diesel oil tank farm with a capacity of 4300 tons by autumn of 1942. A typical airfield, Havannah at Efate, had buried gasoline storage of 5700 tons. Henderson Field at Guadalcanal had storage for 4400 tons of gasoline at about this same time. But consumption continued to exceed expectations, and a year later Espiritu had storage for 72,000 tons of fuel oil, 2900 tons of diesel fuel, 2400 tons of motor gasoline, and 3300 tons of aviation fuel. The pumping system could deliver just over a ton per minute of fuel oil, which was not considered a particularly high rate of delivery. But these were forward bases: Fremantle had storage for 100,000 tons of fuel oil by 1945, and the great base at Pearl Harbor had storage for 563,000 tons of fuel oil when war broke out, and nearly 1.4 million tons when the war ended.

Facilities became more primitive close to the front. In the wilds of the South Pacific, warehouse space was nonexistent and supply dumps often had no more protection than tents. The humidity decomposed cardboard ration boxes and food spoiled quickly. It has been estimated that 40% of rations in the Southwest Pacific were spoiled by the time they reached field kitchens. The Army responded by developing special asphalt-impregnated bags for flour and other dry goods and improved cardboard boxes made of V-Board, which combined fiber and sisal. This reduced wastage in 1944 to 13.6%, though this was still worse than the 9.5% wastage in Europe.

Construction of new bases was a major activity in the Pacific. The first new base construction by the Americans, at Bora Bora, was improvised using stocks and personnel previously assembled for construction of bases in Britain. Operation BOBCAT provided many lessons that were put to use in subsequent base construction at Tongatabu, Samoa, and Efate, but establishment of these bases completely exhausted prewar stocks. The Navy responded by organizing units called Lions and Cubs, with Lions consisting of all personnel and materiel needed for a naval major base and Cubs of all personnel and materiel needed for an advance base. Four Lions and twelve Cubs were initially authorized, and one Lion and three Cubs were ready by July 1942. Cub #1 shipped for Espiritu Santo, but Lion #1 languished on the West Coast for six months before moving to Espiritu Santo, where it was found that the unit required extensive reorganization to meet the specific needs of the base. The Acorns, meanwhile, were taking over eighteen months to organize. These developments called into the question the entire concept of one-size-fits-all base unit organizations.

Instead, the Americans created the Catalog of Advanced Base

Functional Components in March 1943. This could fairly be

described as

the Sears-Roebuck

catalog of naval base development. It was a catalog of

functional components of a naval base, such as a tank farm

or a carrier aircraft service unit, that were prepackaged with all

the

necessary tools, equipment, and personnel. A base commander could

requisition the functional units required for his base, tailored

to

local conditions, but with the finer details already worked out in

advance so that requisition was vastly simplified. The original

catalog

described 79 functional components grouped into 14 categories, but

by

the end of the war, the appendices ran to 479 volumes that

described

each item down to the last screw. It is revealing that this

catalog was

not authorized by any formal directive, but was created on the

initiative of the Director of Base Maintenance, Captain R.W. Cary.

The Japanese logistical arrangements seemed to presuppose a short war. A large reserve of fuel was stockpiled for the Fleet, but estimates of how much fuel would actually be used were low by at least a factor of two. Japanese logistics tended to collapse under pressure, as happened both in New Guinea and at Guadalcanal. Even the Centrifugal Offensive was operated on a logistical shoestring, and 14 Army in the Philippines nearly had its logistics collapse when the campaign went beyond the single month allowed for it in Japanese planning. The Japanese forces suffered severely from malaria when their allocation of quinine ran out, and there were also many cases of beriberi. In part, the weakness of Japanese logistics reflected the much weaker industrial base of Japan relative the United States. The Japanese inferiority in logistics went a long ways towards nullifying her advantage of interior lines of communication.

The shortage of oil

was at the foundation of much of Japan's logistical difficulties.

When

war broke out, the Japanese Navy had managed to

stockpile about 6 million tons of oil. This was thought to be

sufficient for the

first year of war, but consumption greatly exceeded prewar

projections. The Army estimated it would require 800,000 tons

per year while Navy requirements were estimated at 2.5 million

tons

per year and civilian requirements at 1.8 million tons per year.

Actual consumption proved to be at least twice what had been

projected.

By August 1942 the oil shortage had already begun limiting the

kinds of

operations the Japanese could carry out, and this was aggravated

by the

lack of forward oil storage facilities. For example, oil storage

at Truk amounted to just 77,200

tons, enough to completely refuel Yamato

just twelve times. The Japanese attempted to make up the shortage

by

anchoring oilers in Truk lagoon, but this further aggravated the

oiler

shortage. It is likely that fuel

shortages were a significant part of the reason Yamamoto was reluctant

to

commit his battleships in the Guadalcanal campaign.

The Japanese weakness in logistics may have had even darker consequences. Historian Dennis Showalter has suggested (Marston 2005) that the need for the Japanese Army to forage in China was the "entering wedge" for the brutalization of the Japanese Army: "From using a rifle butt on a recalcitrant peasant, it was a short step to teaching the women who their new masters were, and to destroying what could not be carried away." American troops, with their generous supply train, were more often in a position to feed local civilians than to take from them, with all the psychological consequences.

Japanese lack of realism in logistical planning peaked in the U-Go offensive in Burma in 1944.

Hoyt (1993) has offered a biting commentary on

the unreality of the Japanese plan:

Officers and men should carry maximum provisions.

(It was well known that men laden down with supplies could not fight properly.)

Elephants and oxen should be used for hauling stores and equipment.

(A great idea in the time of Genghis Khan, but not in the twentieth century.)

The oxen should be eaten when the provisions run out.

(So then who hauled the equipment?)

Personnel should be prepared to eat grass.

(They did.)

The advance along the road to Imphal from Kohima should be made in two weeks after the commencement of operations.

(Even a fully mechanized army could move only half that fast.)

The road should be repaired after its capture, in order to convey supplies at once by motor vehicle.

(Allied air attacks made the road worse and worse as each day went by.)

Ideally, supplies were moved by ship and train to the combat zone, then transported by a field train transport unit (daikori) to a division depot (yasen soko). From here the supplies were loaded by transport troops (shichohei) onto a combat train (shokori) to be moved to the front line units. The combat train relied heavily on pack animals and the transport troops were organized into a transport battalion for each division, numbering from 2200 to 3700 men with up to 2600 animals. This was organized into five companies, and it was typical for one company to handle small arms ammunition, two to handle artillery rounds, and two to carry rations. The normal combat loadout for a division was a day of supplies, implying replenishment each evening.

Transport troops usually did not complete the full reserve

training course and were ineligible for promotion. Transport

officers were reservists trained at middle schools, not Academy

graduates. As a result, they were scorned by regular troops.

It may be difficult for 21st Century managers, raised in a culture of Amazon and Just In Time, to appreciate how difficult it was to organize the massive logistics of the Pacific War. Merely having sufficient production of necessary items, and shipping and other infrastructure to move it to where it was needed, was not enough. There also had to be a system to determine where men and matériel were needed and ensure that they were at the right place at the right time to be moved through the next link in the supply chain. In the days before modern networked computer systems, this was a considerable challenge.

The assumption with which the United States started the war was that the Naval Transportation Service would coordinate shipping. However, NTS was grossly undermanned and completely overwhelmed by this task. In reality, much of the Navy's auxiliary force was assigned to Base Force, Pacific Fleet, and most of the rest of the Navy's shipping was effectively controlled by the Bureau of Supplies and Accounts. The Army meanwhile concluded that it could not count on the Navy for its shipping needs, and it was reluctant to give up control of its tonnage, which in December 1941 was actually equal to the tonnage under Navy control. The Army had its shipping in almost constant use in late 1941 in its race to deploy to the Pacific before war broke out.

In September 1939, when war broke out in Europe, the Naval Transportation Service had instituted a system of port directors at major ports. The two directors at the most important ports, Captain R.G. Reinicke at the Port of New York and Captain M.C. Davis at the Port of San Francisco, were well chosen, and Davis in particular played a key role in organizing logistics during the first two months of the war. For the first six weeks or so, according to Davis, shipping was readily procured to meet the emergency. Thereafter the Maritime Commission, which by law had the authority to requisition vessels for the Navy during a national emergency, began to take control of the shipping effort.

There were several aspects of the Navy bureaucracy that complicated logistics management. Compared with the Army, the Navy had always been highly decentralized. This reflected the reality that, before the development of radio communications, warships at sea might well go for weeks between communications with higher authority. The mobility of naval forces also required a system of bases whose commanders exercised considerable decentralized authority of their own. Prior to war, with the fleet largely based on the U.S. coasts, the ability of base commanders to maintain sufficient stocks through independent requisitions was never seriously tested. This tradition of decentralized control persisted throughout the Pacific War.

The Navy Department itself was highly decentralized because of

the

system of bureaus. Each of the bureaus was responsible for a

different

area of procurement, and each reported directly to the Secretary

of the

Navy. The Chief

of Naval Operations

thus had little control over the bureaus. This gave considerable

autonomy to the bureaus and considerable power to the bureau

chiefs.The

bureau system persisted until about 1966, when the bureaus were

replaced by systems commands, and it can be argued that these are

simply bureaus by another name. Whatever the merits of the bureau

system, it complicated logistical planning.

Thus, responsibility for coordinating logistics was divided

between

the theater commanders, who developed requirements; the Chief of

Naval

Operations, who helped determine overall global strategy and

priority

between theaters; the naval district commanders, who ran the

system of

rear area bases; the advanced base commanders; and the bureaus.

This

remained substantially the case throughout the war, and the

official

Navy historian of wartime logistics lamented the lack of central

logistical coordination while remaining mystified how the

decentralized

logistics system nonetheless more or less worked (Ballantine

1947). It

seems likely that the logistics effort succeeded largely

because of the initiative of middle-level officers, such as the

Director of Base Maintenance who created the Catalog of Advance

Base

Functional Components described earlier. A similar initiative was

the

Basic Boxed Base Load (BBB) and the corresponding AKS. These were

standardized packages of replenishment supplies for an advance

base or

a stores ship (AKS) that contained clothing and other consumables

for

10,000 men for 60 days. These gave a favorable tradeoff between

reduced

effort in assembling base cargoes and wastage due to imbalances in

consumption versus supply of particular items at particular bases.

A particular deficiency of the Navy system was that the overseas port directors had limited authority, and the Naval Transportation Service essentially lost track of ships once they had left the United States. Another weakness was the naval districts, "the step-children of the naval organization" (Ballantine 1947), which theoretically directed naval activities in the districts but often found that important organizations, particularly logistical organizations, reported directly to the bureaus in Washington. Much of the coordination in logistics was accomplished through the sheer strength of personality of Admiral F.J.Horne, the Vice Chief of Naval Operations, who was able to impose his will on the bureaus in at least some matters.

In late 1943, a Logistics Plan Division was set up in the Navy Department, but this accomplished little. A Logistics Organization Planning Unit set up on 1 April 1944 was somewhat more successful, though requirements of secrecy were a hindrance to developing an Overall Logistics Plan, which of necessity contained considerable highly classified information on future operations. The Summary Control Reports produced under LOPU helped considerably with coordinating procurement. Better inventory controls were put in place. The logistics organization on the West Coast was also revamped. Most of the burden had fallen on the Port Director, San Francisco, who had begun to be overwhelmed by the volume of work. On 12 February 1944, recently retired Admiral Greenslade was appointed Pacific Coast Coordinator of Naval Logistics (Pacornalog), who worked with LOPU but had insufficient authority to accomplish much. Finally, on 8 Novembe 1944, Admiral Roy Ingersoll was named as Deputy Commander in Chief, Deputy Chief of Naval Operations, and Commander Western Sea Frontier, giving him sweeping authority over the 11th, 12th, and 13th Naval Districts and the ability to better coordinate logistics on the West Coast. This helped remove such anomalies as backlogs at San Francisco while Seattle was underutilized.

Most of the coordination of shipping between the services and civilian needs fell to the War Shipping Administration, created by Roosevelt on 7 February 1942. The War Shipping Administrator was the chair of the Maritime Commission, Admiral Land, who was giving sweeping powers that made him what in modern parlance would be called Roosevelt's shipping czar. Under, the WSA, shipping was placed in a common pool to ensure maximum use of both outward and return voyages of every ship. The Army and Navy preferred long-term allocation of shipping to their own pools, but by June 1942 both services had agreed to use the WSA system, except that Navy commissioned auxiliaries remained under Navy control. Except for a very small number of auxiliaries retained by the Naval Transportation Service, the Navy's auxiliaries were allocated either to the Service Forces (which had replaced the Base Force) or the Amphibious Forces. The Naval Transportation Service then became responsible for making detailed forecasts of shipping requirements for the WSA, which were required three months in advance of major operations.

The WSA controlled some 5,865,000 tons of shipping in March 1942,

which had already swelled to 10,725,000 tons of shipping by the

beginning of 1943. Some 22% of this was allocated to the Army and

Navy

in March and 50% by the start of 1943. By this time the supply of

shipping in private hands had been completely exhausted and all

further

increases in shipping controlled by WSA had to come from new

construction.

There was considerable friction between WSA and the Navy. This came to a head in November 1942, when the Navy received a report by Walter Franklin, vice president of the Pennsylvania Railroad, who had reviewed the Navy transport organization. The Franklin Report recommended that operational control of all military shipping be given to the Navy. The WSA retaliated by securing a Presidential directive that WSA was to control the loading of all military cargo except for amphibious assaults and that all assault shipping was to be brought into the WSA pool when not actually involved in combat operations. This exercise in bureaucratic brinksmanship resulted in the formation of the Joint Army, Navy, War Shipping Administration Committee for Ship Operation, which helped clear the air.

Although shipping was the chief bottleneck to logistics, railways

were also brought under the control of the Office of Defense

Transportation, created on 17 December 1941, which allocated all

rail

resources. Unlike the WSA, the ODT allocated block of permits for

rail

resources to each service to use as it saw fit. These were

administered

by the Bureau of Supplies and Accounts for the Navy. Storage space

at

ports was also in short supply. While Navy use of port facilities

increased nine fold by 1944, Navy covered storage space near port

facilities had only doubled.

During the first year of the war, the South Pacific Area sent its requisitions directly to the bureaus in Washington, bypassing both the Base Force and the naval authorities on the West Coast. Logistical channels were highly improvised, beginning with the South Pacific Service Force at Auckland in April 1942. A Joint Purchasing Board was set up to make purchases in New Zealand, which could supply ample fresh food (but little else.) Eventually formal channels were set up from the forces in the South Pacific to Service Squadron, South Pacific (which replaced South Pacific Service Force), then to Subordinate Command, 12 Naval District at San Francisco. However, fuel and ammunition were handled separately, through Service Force, Pacific Fleet.

By early 1944, logistics information was broken down into Basic

Logistics Information, which summarized the strength of the

deployed

forces; Area Logistics Information, which indicated what

stockpiles of

supplies were available in the area; and Shipping Information,

which

prioritized area requirements and indicated what cargoes were

ready for

shipment from the United States. A system of triage of

cargoes

was instituted in which shipments were classified as

indispensable,

necessary, or desirable, in decreasing order of priority.

An under appreciated aspect of the American logistical system is that it began to develop a momentum of its own that often influenced the pacing of offensive operations. Behind the divisions assigned to an amphibious assault were other divisions engaged in advanced training, behind which were divisions deploying from the continental United States. These movements were carefully scheduled to make best use of limited shipping, and a delay in opening a new campaign could disrupt carefully laid plans clear back to the States. The system was referred to as an "automatic" system, defined by CINCPOA as "a system of supply in which the entire impetus is from rear to front. Each element in the supply chain must push supplies forward, without requisitions, requests, or reports from forward units to be served ... by periodic shipments of fixed quantities of supply" (Ballantine 1947).

At the close of the First World War, American naval planner

reckoned that a naval fleet lost 10% of its combat power for every

1000 miles (1600 km) that it operated away from its base. The fortifications clause of

the Washington

Treaty, which forbade the further development of American

bases in the western Pacific, forced the Navy to study the problem

of creating a fleet supply train to allow the fleet to project

naval power far from its permanent bases. This led to innovations

in the design of floating

dry docks and in underway replenishment, and it also

prompted the Navy to create a Service Force as a supply train.

Though the number of auxiliaries was severely limited in

peacetime, when tight budgets meant funding warships would

necessarily have higher priority, the Navy had a good idea of what

would be needed in time of war and how the fleet train might be

mobilized.

The Service Force grew rapidly in the first year of the war, from

77

ships in the Central Pacific in December 1942 to 358. This

made

possible one of the crucial American innovations during the war,

the At

Sea Logistics Service Group. This began with the reorganization of

Service

Squadron Four at Funafuti

as the first floating supply base.

The At Sea Logistics Service Group became the backbone of the logistics tail of the Navy. It amounted to a floating naval base, which by October 1944 consisted of 34 oilers, 11 escort carriers, 19 destroyers, 26 destroyer escorts, and several fleet tugs. These were organized into ten to twelve replenishment task units that could be rotated continuously at sea, with three or four such units (with nine to twelve oilers) forming a replenishment task group that was kept just out of range of enemy land-based aircraft. A replenishment task unit would be relieved by another every few days during active operations, with the relieved task unit proceeding to Ulithi to replenish from merchant tankers. Each replenishment task unit also included an escort carrier to bring forward aircraft and pilot replacements, and all were escorted by additional escort carriers and destroyers. Tugs were assigned to each replenishment task unit and could be sent into the combat zone to tow crippled warships out of the danger zone.

Underway replenishment reached its peak with Service

Squadron

6 (Beary). During

the Iwo Jima campaign, the

squadron delivered

2,787,000 barrels (about 370,000 tons) of fuel oil, 7,126,000

gallons

(26,970,000 liters) of aviation gasoline, and 105,000 barrels

(about

14,000 tons) of diesel oil. Service

Squadron 4 was essentially a floating naval base, complete

with tenders, repair ships, and concrete barges.

The most serious shortage was of provisions storeships,

which could not always bring forward enough fresh and frozen food

for

the fighting fleet. Dry provisions such as beans and Spam had to

be

substituted. Munitions

ships

were also in short supply, and had to be supplemented with Victory ships hastily

converted

as auxiliary munitions ships (AKE).

Some notion of the capability of the fleet train is given by the

following table of supplies delivered via underway replenishment

during

the Okinawa campaign:

| Fuel oil |

10,133,000

barrels |

| Diesel |

323,000 barrels |

| Avgas |

25,573,000

gallons |

| Bombs and

ammunition |

16,375 tons |

| Replacement

aircraft |

998 |

| Replacement

aircrew |

220 |

| Refrigerated

provisions |

2,219 tons |

| Dry

provisions |

4,005 tons |

| Ship's

stores |

575 tons |

| Mail |

15,398 bags |

| Passengers |

1,240 |

| Replacement

personnel |

1,032 |

By the time of the Okinawa campaign, the Navy actually had an

excess of dry provision cargo, and one ship, Ascella, rode at

anchor in Ulithi from 25

February to 13 June 1945 before a use could be found for its dry

cargo. This

created no small stir with War Shipping Administration, which

decried

the waste of cargo tonnage at a time when there was a worldwide

shipping shortage. The excess was due to two factors: First, the

shortage of provisions storeships had finally been made good, and

the

ships in the combat zone naturally preferred fresh to dry

provisions.

Second, about 100 ships were sunk by kamikazes or sent to

the West Coast for repairs

during the Okinawa campaign and no longer had to be supplied by

the fleet train.

The case of Ascella illustrated a pervasive difficulty

with

ship retentions at forward bases, which tied up 18% of total WSA

shipping tonnage by June 1944. The lack of warehouse space led to

the

use of ships as floating warehouses when they were desperately

needed

for carrying supplies. The situation only got worse during the

year,

with retention rising to 30% by November.

An unintended consequence of the efficiency of the American fleet train was that it was actually more efficient to bring in fresh supplies from the West Coast than to bring forward supplies from rear bases left behind by the rapid Allied advance. In other words, roll-up of supply proved more expensive than it was worth.

China was a glaring exception to the generally good Allied

logistics. Chinese troops often went days without food and months

without pay, with obvious consequences for morale. Supplies were

often abandoned when forces relocated. Ch'en Ch'eng complained that

"this phenomenon fully revealed that we do not have the ability to

supply our frontline troops. It showed that China is still a

backward country with poor management" (quoted in Peattie et

al. 2011). China had perhaps 3000 usable vehicles in an army

of million, and was short even of adequate pack animals to move its

forces.

References

Gropman (1997; accessed 2013-6-29)

"Handbook on Japanese Military Forces" (1944-9-15)Kuehn

(2008)

Leighton

and

Coakley (1955)

The Pacific War Online Encyclopedia © 2007-2016 by Kent G. Budge. Index